1. Rusange

Indangagaciro zuruhererekane zikoreshwa mugufunga cyangwa gufungura imiyoboro muri sisitemu kugirango ikomeze imikorere isanzwe ya sisitemu.

2. Ibisobanuro ku bicuruzwa

2.1Ikoranabuhanga risabwa

2.1.1 Gushushanya no gukora: API600 、 API603 、 ASME B16.34 、 BS1414

2.1.2 Igipimo cyanyuma cyo guhuza : ASME B16.5 、 ASME B16.47 、 ASME B16.25

2.1.3 Imbona nkubone cyangwa iherezo kurangira : ASME B16.10

2.1.4 Kugenzura no kugerageza : API 598 、 API600

2.1.5 Ingano yizina : MPS2 ″ ~ 48 ″ rat Urutonde rwizina nomero : Icyiciro150 ~ 2500

2.2 Imyanya y'uruhererekane ni intoki (ikoreshwa binyuze mu ntoki cyangwa agasanduku k'ibikoresho) irembo ry'irembo rifite impera ya flange n'impera yo gusudira .Igiti cya valve kigenda gihagaritse.Iyo uhinduye intoki ku isaha, irembo riramanuka kugirango rifunge umuyoboro;iyo uhinduye intoki ku isaha, irembo rirazamuka kugirango rifungure umuyoboro.

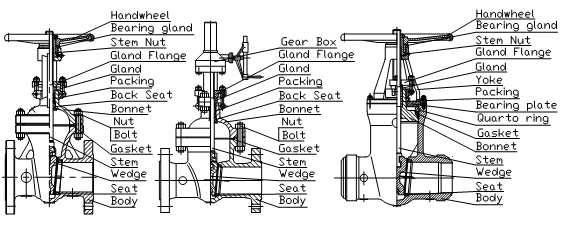

2.3 Imiterere reba Ishusho.1, 2and3.

2.4 Amazina nibikoresho byibice byingenzi biri kurutonde rwa 1.

| Izina ry'igice | Ibikoresho |

| Umubiri na bonnet | ASTM A216 WCB、ASTM A352 LCB、ASTM A217 WC6、 ASTM A217 WC9、ASTM A351 CF3、ASTM A351 CF3M ASTM A351 CF8、ASTM A351 CF8M、ASTM A351 CN7M ASTM A494 CW-2M、Monel |

| irembo | ASTM A216 WCB、ASTM A352 LCB、ASTM A217 WC6、 ASTM A217 WC9、ASTM A351 CF3、ASTM A351 CF3M ASTM A351 CF8、ASTM A351 CF8M、ASTM A351 CN7M ASTM A494 CW-2M、Monel |

| intebe | ASTM A105、ASTM A350 LF2、F11、F22、 ASTM A182 F304(304L、 、ASTM A182 F316(316L) ASTM B462、Ifite.C-4、Monel |

| uruti | ASTM A182 F6a、ASTM A182 F304(304L) 、ASTM A182 F316(316L、 、ASTM B462、Ifite.C-4、Monel |

| Gupakira | Igishushanyo mbonera cya grafite、PTFE |

| Kwiga / ibinyomoro | ASTM A193 B7 / A194 2H、ASTM L320 L7 / A194 4、 ASTM A193 B16 / A194 4、ASTM A193 B8 / A194 8、 ASTM A193 B8M / A194 8M |

| Igipapuro | 304(316)Igishushanyo、304(316、 、Ifite.C-4、 Monel、B462 |

| Impeta y'icyicaro / Disiki / hejuru | 13Cr、18Cr-8Ni、18Cr-8Ni-Mo、NiCu、25Cr-20Ni、STL |

3. Kubika, kubungabunga, Kwinjiza no gukora

3.1 Kubika no kubungabunga

3.1.1 Imyonga igomba kubikwa mucyumba cyumye kandi gihumeka neza.Impera zanyuma zigomba gucomekwa hamwe.

3.1.2.

3.1.3 Niba igihe cyo kubika kirengeje amezi 18, indangagaciro zigomba kugeragezwa kandi zigomba gukorwa inyandiko.

3.1.4 Ibyingenzi byashyizweho bigomba gusuzumwa no gusanwa buri gihe.Ingingo nyamukuru zo kubungabunga zirimo ibi bikurikira:

1) Gufunga isura

2) Valve stem na valve stem nut.

3) Gupakira.

4) Kubeshya hejuru yimbere yumubiri wa valve na bonnet

3.2

Mbere yo kwishyiriraho, menya neza ko indangagaciro ya valve (nk'icyitegererezo, DN, 3.2.1PN n'ibikoresho) byashyizweho ikimenyetso ukurikije sisitemu y'imiyoboro.

3.2.2 Mbere yo kwishyiriraho, genzura neza ibice bya valve no gufunga isura.Niba hari umwanda, sukura neza.

3.2.3 Mbere yo kwishyiriraho, menya neza ko bolts zose zifunzwe neza.

3.2.4 Mbere yo kwishyiriraho, menya neza ko gupakira byafunzwe neza.Ariko, kugenda kwa stem stem ntigomba guhungabana.

3.2.5 Ahantu hashyizwe na valve hagomba koroshya kugenzura no gukora.Umwanya ukwiye ugomba kuba umuyoboro utambitse, intoki ziri hejuru, na stem stem irahagaritse.

3.2.6 Kubisanzwe bifunze valve, ntibikwiye kuyishyira ahantu igitutu cyakazi ari kinini cyane kugirango wirinde kwangirika kwuruti.

3.2.7.

1) Gusudira bigomba gukorwa nuwasudira ufite icyemezo cyujuje ibyangombwa byo gusudira byemejwe n’ikigo cya Leta gishinzwe guteka no gukanda;cyangwa gusudira wabonye impamyabumenyi yo gusudira yasobanuwe muri ASME Vol.Ⅸ.

2) Ibipimo byo gusudira bigomba gutoranywa nkuko bigaragara mu gitabo cyizeza ubuziranenge bwibikoresho byo gusudira.

3) Ibigize imiti, imikorere yubukanishi hamwe no kwangirika kwangirika kwicyuma cyuzuza icyuma cyo gusudira bigomba guhuzwa nicyuma fatizo.

3.2.8 Ubusanzwe valve yashyizweho, guhangayika cyane kubera inkunga, ibikoresho hamwe nu miyoboro bigomba kwirindwa.

3.2.9 Nyuma yo kwishyiriraho, mugihe cyo kugerageza igitutu cya sisitemu y'imiyoboro, valve igomba gukingurwa byuzuye.

3.2.

3.2.11 Guterura: ntukoreshe intoki kugirango uzamure kandi uzamure valve.

3.3 Gukoresha no gukoresha

3.3.Ntishobora gukoreshwa muguhindura ubushobozi bwo gutembera.

3.3.2 Mugihe ufunguye cyangwa ufunze valve, koresha intoki aho gukoresha lever infashanyo cyangwa ukoreshe ikindi gikoresho.

3.3.3 Ku bushyuhe bwakazi, menya neza ko umuvuduko uhita uri munsi ya 1.1 inshuro zerekana ko akazi kerekana umuvuduko wubushyuhe muri ASME B16.34.

3.3.4.

3.3.5 Gukubita no gutangaza valve birabujijwe mugihe cyo gutwara, kwishyiriraho no gukora.

3.3. y'amazi.

3.3.7.

3.3.

3.3.9 Mugihe habaye amazi ateye akaga, nkibisasu biturika, byaka.Ibicuruzwa bifite ubumara, okiside, birabujijwe gusimbuza gupakira munsi yigitutu (nubwo valve ifite imikorere nkiyi).

3.3.

3.3.11 Byemerewe ubushyuhe bwakazi:

| Ibikoresho | ubushyuhe | Ibikoresho | ubushyuhe |

| ASTM A216 WCB | -29~425 ℃ | ASTM A217 WC6 | -29~538 ℃ |

| ASTM A352 LCB | -46~343 ℃ | ASTM A217 WC9 | --29~570 ℃ |

| ASTM A351 CF3(CF3M) | -196~454 ℃ | ASTM A494 CW-2M | -29~450 ℃ |

| ASTM A351 CF8(CF8M) | -196~454 ℃ | Monel | -29~425 ℃ |

| ASTM A351 CN7M | -29~450 ℃ |

| - |

3.3.12 Menya neza ko ibikoresho byumubiri wa valve bikwiriye gukoreshwa mubidukikije birinda ruswa kandi birinda ingese.

3.3.13 Mugihe cya serivisi, suzuma imikorere yikimenyetso nkuko imbonerahamwe ikurikira:

| Ingingo yo kugenzura | Kumeneka |

| Guhuza hagati ya valve umubiri na bonnet | Zeru |

| Ikidodo | Zeru |

| Intebe | Nkurikije ibisobanuro bya tekiniki |

3.3.14 Kugenzura buri gihe kwambara kwambara kashe.Gupakira gusaza no kwangirika.Kora gusana cyangwa gusimbuza mugihe ibimenyetso bibonetse.

3.3.15 Nyuma yo gusana, ongera uteranye kandi uhindure valve, imikorere yikizamini kandi ukore inyandiko.

3.3.16 Kwipimisha no gusana imbere ni imyaka ibiri.

4. Ibibazo bishoboka, ibitera n'ingamba zo gukosora

| Ibisobanuro by'ikibazo | Impamvu zishoboka | Ingamba zo gukemura |

| Kumeneka | Gupakira bidahagije | Ongera ushimangire ibinyomoro |

| Umubare udahagije wo gupakira | Ongeraho ibindi bipakira | |

| Gupakira byangiritse kubera serivisi zigihe kirekire cyangwa kurinda bidakwiye | Simbuza gupakira | |

| Kureka kuri valve wicaye mumaso | Kwicara mu maso | Kuraho umwanda |

| Kwambara mu maso | Gusana cyangwa gusimbuza impeta yintebe cyangwa irembo rya valve | |

| Kwicara mu maso byangiritse kubera ibintu bikomeye | Kuraho ibintu bikomeye mumazi, gusana cyangwa gusimbuza impeta yintebe cyangwa irembo rya valve, cyangwa gusimbuza ubundi bwoko bwa valve | |

| Kumeneka uhuza umubiri wa valve na valve bonnet | Bolt ntabwo ifunzwe neza | Funga icyarimwe |

| Kwicara kwangiritse hejuru yumubiri wa valve na valve bonnet flange | Sana | |

| Igikoresho cyangiritse cyangwa cyacitse | Simbuza gasike | |

| Guhinduranya bigoye byintoki cyangwa irembo rya valve ntibishobora gufungurwa cyangwa gufungwa | Gupakira cyane | Kurekura muburyo bukwiye |

| Guhindura cyangwa kugoreka kashe ya glande | Hindura glande | |

| Imyanda yangiritse | Kosora urudodo kandi ukureho umwanda | |

| Yambarwa cyangwa yamenetse ya valve stem nut | Simbuza ibiti by'imbuto | |

| Igiti cya valve | Simbuza igiti cya valve | |

| Ubuyobozi bwanduye bwirembo rya valve cyangwa umubiri wa valve | Kuraho umwanda hejuru yubuyobozi |

Icyitonderwa: Umuntu wa serivisi agomba kuba afite ubumenyi nuburambe hamwe na valve.

5. Garanti

Iyo valve imaze gukoreshwa, igihe cya garanti ya valve ni amezi 12, ariko ntikirenza amezi 24 nyuma yitariki yo gutanga.Mugihe cya garanti, uwabikoze azatanga serivise yo gusana cyangwa ibice byabigenewe kubusa kubwibyangiritse bitewe nibikoresho, akazi cyangwa ibyangiritse mugihe icyo gikorwa ari cyo.

Igihe cyoherejwe: Gicurasi-19-2022